Cabling Industry — Real-Time Tag-less Tracking at Scale

10,000+ metallic coils tracked by monitoring only 12 forklifts. A full 3D, indoor & outdoor RTLS solution with a 12-month payback period.

Client Overview

For over 100 years, the company has manufactured railway, fire-safety and power cables.

The annual material turnover reaches levels comparable to small national economies, making even minor inefficiencies extremely costly.

Business Goal

Reduce production and logistics costs using reliable, real-time data

- Eliminate waste in production and supply chain processes

- Reduce human errors in material handling

- Optimize forklift navigation and utilization

- Improve visibility of Work-In-Process inventory

- Use one RTLS infrastructure for multiple operational use cases

Key Challenges

One of the harshest environments for radio-based tracking

- Massive metal objects causing signal reflections

- Strong magnetic fields

- Continuous coil rotation and collisions

- High mechanical stress on tracked assets

Traditional RFID or Bluetooth-based systems fail under these conditions.

Solution Overview

Tag-less 3D tracking delivered by Zealabs

Instead of tagging 10,000+ coils, Zealabs implemented a tag-less RTLS approach by tracking only 12 forklifts that handle all material movements.

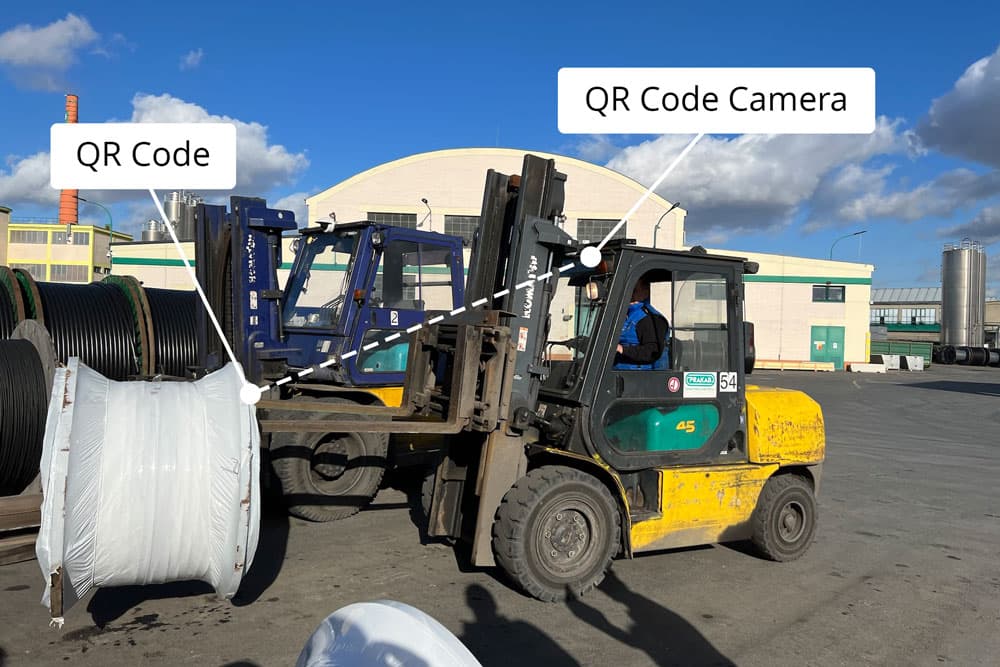

Each forklift was equipped with:

- UWB localization tag (for X, Y position)

- Lift sensor (Z position / height)

- Weight sensor (automatic load detection)

- QR camera (product identification)

- LCD display (driver navigation & instructions)

- Connectivity unit (independent cellular connection)

Hardware installation time: ~28 seconds per forklift.

How It Works

Forklift loads a coil

Camera reads the coil's QR code

Weight sensor confirms loading

UWB system records real-time XYZ position

Full movement trajectory is stored until unloading

ERP system is updated automatically

This ensures full 3D tracking, complete traceability and zero manual scanning.

System Scale

Core Use Case: Reducing Production Costs

Cable production requires combining 12–18 different coils per finished cable. Previously, uncertainty in material selection forced the company to:

Use excess copper as a quality buffer, accept higher material consumption, and rely on manual verification.

With RTLS: Exact coils and batches are known for every cable. Material usage is optimized per cable specification. Full backward traceability is achieved.

Operational Improvements

1. Search & Find

Forklift drivers see real-time locations of coils on an in-cab display. Coils are sorted by proximity to reduce travel distance.Savings: €10,400 per month from eliminated search time.2. Guided Navigation

The system calculates optimal routes considering traffic (other forklifts & personnel), active work orders, and destination verification. Forklift guidance works similarly to Google Maps or Waze.Impact: 2 forklifts eliminated (12% reduction in handling costs)3. Warehouse Utilization

With predictable trajectories and real data: Storage zones are filled systematically, dead space is eliminated, and layout planning improves.Result: 15% increase in warehouse space utilization4. Safety & Automation

No manual scanning outside the forklift cabin. Reduced operator exposure to hazards. Automatic load/unload detection.5. Inventory & WIP Control

Production managers gain real-time WIP visibility, stock level control, and reduced stockouts.6. Advanced Analytics

Heatmaps and trajectory analysis reveal bottlenecks, inefficient paths, and process improvement opportunities.7. Boosted OEE

Forklifts now provide run/stop times, loaded vs unloaded time, and distance traveled. This enables data-driven optimization of manipulation equipment.Results Summary

Why This Solution Works

- No batteries on tracked assets → low maintenance

- Works in extreme metallic environments

- Indoor + outdoor tracking in one system

- Scalable and ERP-integrated via API

"The ROI was achieved by just one use case. All the others exceeded our expectations."